The most common, man-made, building material is undoubtedly concrete. Each ton of cement produces about 900 kg CO2. But researchers have observed that the addition of hemp fiber to concrete resulted in a high performing, eco-friendly construction material. Hemp is not a new construction material. Archaeologists have confirmed the use of hemp fiber (also called ‘shive’) in the construction of a bridge, dated to the 6th century AD, in southern France. Hemp is a fast-growing plant that has prospect not only in terms of biomass energy recovery, but also of material in the construction field in accordance with the principles of sustainable development. What is Hempcrete? Hempcrete is non-toxic, bio-composite mixture of hemp shive, lime binder and water. The hemp shive is the wooden part of the hemp stem (approximately 2/3 of stem) in the processing of hemp plant to the fiber. Commonly, it is lime or cement but could be any combination of elements to make a hemp binder. A lightweight material, it is about one eighth the weight of concrete. Hempcrete can be used to construct walls, floors and roofs; or molded (monolithic), sprayed or precast (e.g. hemp bricks or panels). Generally, it is inserted as infill insulation around the structural framing of the house. Often for clarity, hempcrete is referred to as Lime Hemp Composite (LHC). Outstanding Thermal Properties A 300mm thick hempcrete wall has an R-value - a measure of thermal resistance - of 4.2 while a 200mm thick floor infill will achieve an R-value of 4.0. The higher the R-value, the higher the resistance. For reference, snow has an R-value of 1 per inch.

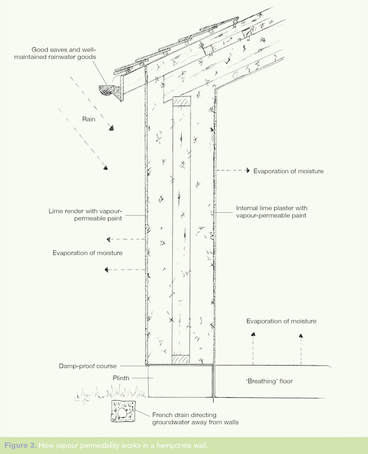

Walls can range from 250mm to 500mm thick. Generally for most applications, 300mm overall thickness will provide the best results from a thermal and acoustic performance perspective. Fire tests on a 300mm thick hempcrete wall gave 73 minutes for structural adequacy/integrity/insulative capacity to fail. Carbon Negative Material Like other plant products by photosynthesis, hemp absorbs CO2 from the atmosphere as it grows, retaining the carbon and releasing the oxygen. This process is called carbon sequestration, and involves the capture of carbon and the long-term storage of atmospheric carbon dioxide. It has been proposed as a way to slow the atmospheric and marine accumulation of greenhouse gases. Even when the hemp shiv is mixed with concrete (80-90% of hemcrete composition as hemp shiv), it is able to still sequester CO2. The lime-based binder absorbs carbon from the air continuously over time, petrifying the hemp shiv. Each tonne of lime-based hempcrete is estimated to absorb and sequester 249 kg of CO2 over a 100 year lifecycle. Generally, hempcrete is estimated to sequester 110kg per cubic meter (depending on transportation use) which means large-scaled projects have the capabilities of drawing tonnes of CO2 out of the atmosphere. Less Energy Usage Roughly 80% of the environmental impact of a building comes from the energy used, via air conditioners/heaters, during its life. Hempcrete houses are thermally efficient therefore homeowners and office workers will expend less energy during the building’s life of use. For tropical climates where air conditioners are constantly used for long periods to combat the heat and humidity, a hempcrete house will dehumidify and cool down quickly without the need for the air conditioner to stay on. Due to its ability to absorb moisture from the air, hempcrete will stabilize the relative humidity for long periods without the need for air conditioning. For other climates where heaters are constantly used for long periods to combat the cold and damp, a hempcrete house will dehumidify and heat up quickly without the need for the heater to stay on. Hempcrete is also a breathable porous fabric designed to pass water vapor but not liquid. Hempcrete walls need to “breathe” to ensure there is interaction with both the internal and external environment – this allows for the hempcrete to absorb/desorb water vapor (humidity) as well as the ability to buffer temperature fluctuations. Non breathable walls risk that that building will suffer the sick building syndrome or sweaty building syndrome, serious complications of water vapor being absorbed into the building not being able to be released. Recyclable Material One of the best things about hempcrete is that it is recyclable. Any waste on the building site can be reused in a mix or spread out as mulch. If a building made of hempcrete needs to be demolished, all the hempcrete can be recycled for a new mix. Hempcrete is an ideal building material where recyclability of building materials is a major factor. Unlike concrete, hempcrete doesn’t need huge machinery to break it up for reuse. It is able to be broken up by hand or use a hammer mill for large quantities – either method requires little energy. ReferencesBedlivá, H. and Isaacs, N. (2014). Hempcrete – An Environmentally Friendly Material?. Advanced Materials Research, 1041, pp.83-86. https://doi.org/10.4028/www.scientific.net/AMR.1041.83

Goasdoue, M. (2017). Hempcrete.com.au: The Australian Hempcrete Technologists. [online] Hempcrete.com.au. Available at: http://www.hempcrete.com.au/index.php?option=com_content&view=article&id=23&Itemid=24 [Accessed 23 Sep. 2017]. Turnbull, S. (2017). High hopes for hemp in Australian building industry. [online] ABC News. Available at: http://www.abc.net.au/news/2017-09-18/high-hopes-hemp-could-revolutionise-australian-building-industry/8954994 [Accessed 21 Sep. 2017].

0 Comments

Leave a Reply. |

This feed contains research, news, information, observations, and ideas at the level of the community.

Archives

June 2024

Categories

All

|

RSS Feed

RSS Feed